Nowadays, more and more laptops are used in our daily life, the quality of the notebook is more and more important. The screen display is directly related to people's visual enjoyment. Backlight module plays a key role, and the diffusion film of the backlight module plays a role of soft light, which is an essential part. Light diffusion film's property relates to the optical effect of the backlight unit(BLU).

The main function of light diffusion film is to provide a uniform surface light source for LCD. The main material for making diffusion film is PET-polyethylene terephthalate.

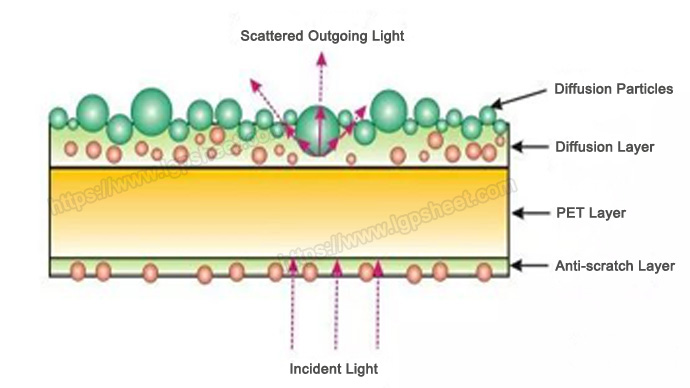

The diffusion film is mainly composed of three layers, including the anti-scratch layer at the bottom, the transparent substrate layer at the middle and the diffusion layer at the top. The working principle of light diffusing sheet is that the light injects into anti-scratch layer from the bottom, penetrates the transparent substrate and then scatters in diffusion layer. Diffusion layer is full of diffusion particle. Most of them are spherical and the function is similar with convex lens. Different particle size of diffusion particles ensure the light cannot shoot our from the diffusion layer directly and make the light more uniform.

Generally speaking, 14 inches laptops are suitable for many occasions, with good performance, good heat dissipation, large visual area and moderate portability. China light diffuser sheet supplier GUTE TEK Plastic manufactures 14 inch Optical diffusion film for liquid crystal display(LCD) backlight unit of the notebook.

Light Diffuser Film

|

Item |

Content |

Unit |

Results |

Method |

|

|

Thermal Property |

Thermal shock test |

60℃, 90%RH, 500h |

/ |

Good |

GUTE Method |

|

Thermal shock test |

-25℃*1h-65℃*1h, 60%RH, 50cycles |

/ |

Good |

||

|

Heat stability |

85℃, 240h |

/ |

Good |

||

|

Heat stability |

-20℃, 240h |

/ |

Good |

||

|

Mechanical Property |

Tensile Strength |

MD(Machine Direction) |

MPa |

≥80 |

GB/T 13542.4-2009 |

|

TD(Transverse Direction) |

MPa |

≥73 |

|||

|

Tensile Elongation |

MD(Machine Direction) |

% |

≥70 |

GB/T 13542.4-2009 |

|

|

TD(Transverse Direction) |

% |

≥49 |

|||

|

Heat Shrinkage |

MD(Machine Direction) |

% |

≤0.26 |

GB/T 13542.4-2009 |

|

|

TD(Transverse Direction) |

% |

≤0.07 |

|||

GET IN TOUCH WITH US

If you have more questions, write to us.

Recommended

They are all manufactured according to the strictest international standards. Our products have received favor from both domestic and foreign markets.

They are now widely exporting to 200 countries.