The LED light guide plate short form is LGP,which is made of acrylic, MS, PC and PS raw material.

In different industry,there is difference preference of material.In lighting industry mostly LGP is PMMA LGP and PS LGP;In TV industry mostly use acrylic light guide plate and MS LGP;In display industry and Illuminated sign industry such as the backlight module and the light box mostly use acrylic Light guide plate or acrylic light guide film.The material option also depends on the cost of the product.

Today we will mainly talk about the way of processing the dot of light guide plate.

Thermal embossing process uses the physical principle of plastic deformation when LGP material heated to complete the processing of dots.

Before the light guide plate being processed, two preheated rollers are rotating in opposite directions and the gap between rollers is adjusted, and the rollers are covered with stainless steel templates with processed micro-structure (PATTERN). The LGP is sent to the middle of the two rollers through the transfer device, and the temperature of the two rollers and the stencil is transferred to the contact surface of LGP (theoretically, it is a linear contact), at the same time, the surface of LGP is plastically deformed due to heat and pressure, and the microstructure (PATTERN) on the stencil is completely transferred to the surface of LGP to complete the processing of the microstructure (PATTERN dot) of LGP.

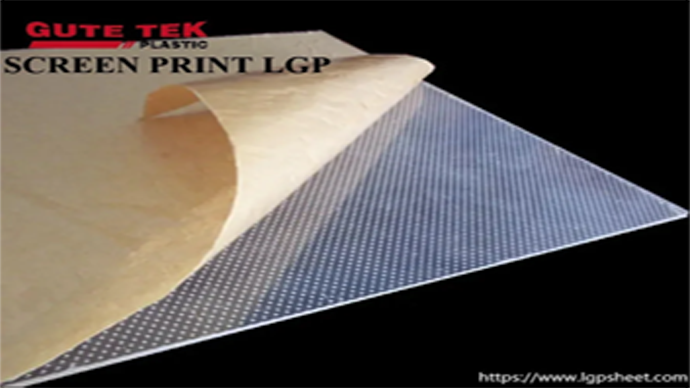

Screen printing light guide plate is a kind of process that the ink printed on the light guide plate through the screen,so that the light through these dots to form a uniform light, this process is relatively simple, easy to control.It is early explicated in the ultra-thin light box industry, also until now has been widely used process.

Laser engraving process of light guide plate: Engraving is a physical process, the service life of the light guide plate is mainly related to the quality of the plexiglass substrate. Compared with the screen printing LGP,the laser dotting PMMA the service life is longer. There was a case,one subway station used the screen print PMMA LGP for ultra-thin light box,the light has been declined seriously less than 2 years;

The maxim width of engraved light guide plate is1.2M, the light guide uniformity can still reach more than 80%; Especially large size,the laser dotting plexiglass LGP or acrylic light guide plate, better light guide efficiency, more stable performance. 10MM thickness engraved light guide plate with the width of 1.2M, with the 30W light source, the surface illumination can reach more than 2000LUX.

Laser dotting process is very flexible, not like hot embossing print LGP and the screen print LGP,which need stencil and the templates separately.Laser light guide plate can be made and cut in any size, also individual specifications of special plate making. The laser dotting PMMA LGP for the production of large quantities but many specifications of products such as luminous signs, the advantages are obvious.

GET IN TOUCH WITH US

If you have more questions, write to us.

Recommended

They are all manufactured according to the strictest international standards. Our products have received favor from both domestic and foreign markets.

They are now widely exporting to 200 countries.